Introduction

Chemical engineering for kids: Chemical engineering is an important field of study for children of all ages. It is both a science and an engineering discipline that applies mathematics, chemistry, biology, economics, and other scientific principles.

Kids can learn chemical engineering to understand how chemical processes work, as well as how to make changes in those processes to create new ideas, products, or materials.

This introduction will explore the ways that chemical engineering can benefit children and how they can get started.

What is chemical engineering?

Chemical engineering is a field of engineering that combines physical science, mathematics, and economics to convert raw materials into useful products. Numerous industries use chemical engineering including oil refineries, the food industry, pharmaceuticals, polymers and petrochemicals.

Unlike other science-based fields such as physics or chemistry, chemical engineers design and develop products as well as processes for their production. Chemical engineers apply scientific principles to industrial processes in order to create a vast range of useful items from fuel to medicines. For example, they play a major role in designing the plants where crude oil is refined into gasoline or diesel fuel. They are also adept at using limited resources such as electricity, heat and water efficiently so that their production processes are both cost-effective and environmentally responsible.

Another area of specialty for many chemical engineers involves designing new materials such as fabrics or plastics that can be used in consumer goods or medical treatments. This can involve experimenting with different properties of substances around us such as texture and moisture resistance so that they become more versatile or usable products with better performance characteristics.

Overall, chemical engineering plays an essential role in helping to meet our needs while maintaining ecological balance on our planet. From manufacturing the objects that appear on store shelves to protecting the environment from hazardous substances it helps ensure both economic development and environmental protection go hand-in-hand.

Overview of the different branches of chemical engineering

Chemical engineers often specialize in one or more branches of complex chemical processes: bioengineering, energy engineering, nanotechnology, metallurgy engineering, materials engineering, and process engineering.

Bioengineering involves the design and development of biological systems that can be used in medical devices or treatments. Energy engineering refers to designing more efficient forms of energy production or storage. Nanotechnology focuses on developing smaller materials with greater functionality for uses ranging from biomedical imaging to renewable energy applications. Metallurgy deals with the physical behavior and properties of metals used for components in a variety of products such as aircraft engines to auto parts. Materials engineers focus on improving existing materials such as plastics or alloys for use in a variety of industries from automotive to aerospace. Process engineers specialize in optimizing chemical processes from refining oil to creating synthetic rubber.

Each discipline within chemical engineering requires a specialization that has its own unique skillset and its own research focus area. Specialization helps chemical engineers better serve society by providing focus on real-world problems related to the different aspects of chemical engineering – pollution control, product design, economic analysis or sustainability issues such as renewable energy sources or waste treatment solutions are just some examples among many others making this research field one very exciting area to work in!

Chemistry Basics

Chemical engineering is an interesting area of science which can be fun to learn for kids. Understanding the basics of chemistry is the first step to becoming a successful chemical engineer. This includes learning about elements, their properties and reactions.

In this section, we will have an overview of the fundamentals of chemistry, which will be essential for any kid interested in the field of chemical engineering.

Introduction to the periodic table

The periodic table is one of the most important tools of chemistry. It is a chart that organizes the chemical elements by their atomic structure and properties. All elements are organized into groups on the table, which can offer insight into how they behave and interact.

Atoms are made up of a small nucleus containing protons and neutrons, around which electrons spin in layers called shells or orbitals. The number of protons determines the element’s identity, since all atoms with the same number of protons are identical. This means that there are only 118 distinct elements on Earth today, but because these elements can combine in different ways to form compounds, millions of substances exist!

Each element is classified as either a metal (generally shiny solids that conduct electricity) or non-metal (usually dull solids), with fourteen ‘transition metals’ falling between them. We can also categorize elements by whether they are solid, liquid or gas at room temperature.

To remember chemical behaviors and reactivities, we group similar elements together on an eighteen-column grid – the periodic table. This way, we have an organized view of how common properties such as boiling point differ between one element and another when traveling down a certain column or across different rows.

Properties of elements

Elements are the building blocks of all matter in the world. It is important to understand their properties in order to understand the structure and composition of substances. In its simplest form, an element is a pure substance that cannot be broken down into simpler components by either physical or chemical means. The periodic table consists of 114 elements, each with their own unique properties based on their structure and number of protons or neutrons they possess.

The properties of elements can be divided into three main categories: physical, chemical, and atomic. Physical properties describe elements based on their observable characteristics such as color, odor, shape, etc., while chemical properties refer to how elements interact with other substances when combined or exposed to various conditions like heat or pressure. Atomic structures determine most of an element’s physical and chemical properties – for example, carbon’s four electrons determine its ability to form four covalent bonds with other elements. There are many more complex details that determine an element’s behavior when creating molecules and compounds with other substances as well.

- Physical Properties: Color, state (solid/liquid/gas), density and melting point are all examples of physical properties.

- Chemical Properties: Reactivity (which influences reactivity), flammability/inflammability, acidity/basicity (pH value) are all examples of chemical properties.

- Atomic Properties: Electron configuration and number of protons/neutrons are examples of atomic properties that dictate an element’s behavior in terms of bonding powers or reactivity levels among other factors.

Introduction to chemical reactions

Chemical reactions form the basis of chemistry and are important for everyday life. A chemical reaction is a process that involves the rearrangement of the atoms of reactant molecules to different products. It has been defined as “a process in which one or more substances, the reactants, are converted to one or more different substances, the products”.

For example, when combustion takes place evaporated gasoline combines with oxygen from ambient air it creates an exothermic reaction; meaning energy is released in form heat, light and sound. This happens during fireworks (using gunpowder as another example) when energy stored in fuel is given off rapidly and spectacularly due to combustion reactions. Rusting is also an example of a chemical reaction which occurs when iron reacts with oxygen, water and sometimes other chemicals leading to the formation of rust—iron oxide.

Reactions can occur at various rates depending on different factors such as catalyst concentrations and temperature; where greater amounts will speed up reactions while lower amounts will slow them down. Reactions can also release or absorb energy which can also affect its rate too; where exothermic ones with heat tend to speed up while endothermic ones absorb enough energy from surroundings (like mixing cold water droplets together) tend to slow down changes from occurring.

Processes and Equipment

By understanding the processes and equipment used in this branch of engineering, kids can develop a better understanding of how chemical engineering is used to produce products.

This section will cover the basics of chemical engineering processes and equipment.

Overview of common processes used in chemical engineering

Chemical engineering involves the integration of several scientific and operational activities, such as production, design, research, quality control and safety. This wide range of activities means that chemical engineers must utilize numerous tools, processes and technologies in order to create efficient operations and maintain safety standards.

Common processes used by chemical engineers include:

- Crystallization: Crystallization is a process by which solid materials separate out of solutions at specific temperatures when ingredients become insoluble in liquid phase. It is commonly used to purify or refine products such as sugars and proteins.

- Filtration: Filtration is a process used to separate solids from liquids or gases by passing them through a porous medium or filter bed. Common filter beds include sand filters, cloth filters, paper filters or centrifugal filters.

- Distillation: Distillation is a process that separates liquid mixtures based on their boiling point differences. This can be done through simple distillation, fractional distillation or steam distillation techniques depending on desired purity levels for the product being extracted from the mixture.

- Absorption/Stripping: Absorption/stripping is an economic mechanism that removes volatile compounds from pressurized gases by contacting them with liquids such as water or oil based solutions containing absorbents such as amines, glycols and activated carbons. The absorbed molecules are eventually stripped out of the solution before being released into the atmosphere again.

In addition to these processes, several pieces of equipment are commonly used by chemical engineers in order to achieve desired results including reactors (vessels specifically designed for chemical reactions), pumps (to transfer fluid), heat exchangers (for transferring heat), columns (for separating liquids) and separators (for separating gases).

Types of equipment used in chemical engineering

Equipment can range from basic laboratory tools, such as beakers, to large industrial-scale systems like boilers or distillation columns. The types of equipment used in chemical engineering vary depending on the area of focus, but some of the most common pieces include reactors, filters and pumps.

- Reactors are a type of vessel used for processing chemicals on an industrial scale. Reactors come in many sizes and shapes and are designed to take a raw material such as wastewater from a factory or oil from an oil refinery and heat it up or pressurize it until it reaches a desired state. Reactors can be heated externally by applying heat energy to their exterior walls or internally, typically by burning natural gas inside the reactor’s chamber.

- Filters are also commonly found in chemical processing plants, where they are used to separate particles that cannot pass through the filter’s small pores with those that can. Filters can be paper-based membranes or they can be mechanical filters with steel discs arranged in a circular pattern so that particles smaller than each disc’s width will be blocked out. This kind of filtering allows for highly purified products in processes like distillation or purification systems.

- Finally, pumps are often essential components when moving fluids between different process stages within a plant using pipes or tubing. Positive displacement pumps use rotating mechanisms to move liquid at consistent rates by forcing fluids through pressure valves while centrifugal models use spinning blades inside hollow tubes to create outward jets which propel mixtures through channels at controlled velocities. Pumps come in many designs but all provide reliable performance during chemical production processes involiving liquids under pressure (such as those often found within power generation plants).

Applications

Chemical engineering plays a crucial role across a wide range of industries. From food production to medicine manufacturing, the principles of chemical engineering are essential for optimizing processes and creating solutions.

In terms of applications, chemical engineering is used for creating materials and products, designing processes, and analyzing the properties of chemical compounds and materials in a variety of settings.

Let’s take a look at a few of the applications of chemical engineering.

Overview of common applications of chemical engineering

Here are some of the most common applications of chemical engineering:

- Food Processing: Chemical engineering is widely used in food processing. Products like sugars, fats and oils are obtained from raw materials like grains or plants. These products can be further processed into more complex substances such as food additives, flavors and colorings.

- Pharmaceuticals: Pharmaceuticals are highly regulated industries due to the importance placed on safety when it comes to medicine. However, chemical engineers play a large role in the manufacture of drugs for human or animal use by controlling processes such as mixing ingredients according to precise recipes, measuring temperature and pressure accurately throughout processes where drug compounds are obtained from different sources before finally packing them into tablet or capsule forms which can be swallowed or injected safely without any risk to health.

- Biotechnology: From producing biodegradable plastics used for packaging purposes to manufacturing pharmaceuticals from biological sources (for instance recombinant DNA technology), chemical engineers have had an important role in breakthroughs for microbial fermentation process control systems and bio-separations technologies involved with gene-protein manipulations essential for ascertaining promising medical treatments with fewer side-effects than conventional medicines.

- Petroleum Processing: The petroleum industry requires expert management skills on the part of chemical engineers when dealing with vast quantities of petroleum extracted from underground formations through extraction operations such as drilling or fracking prior to their refining into combustible fuels such as gasoline and propane while minimizing environmental emissions under strict government regulations.

- Fertilizers & Pesticides: Chemical reactions involving nitrogen fixation methods (synthetic or natural) feature prominently here for achieving our need for fertilizers seen with plant nutrition cycles required for agricultural production purposes where healthy soil plays a key rule when it comes to producing highly nutritious agro-chemical products intended not just for human consumption but also animal feed supplements as well as free livestock rearing services often given away via NGOs working hard at global poverty alleviation schemes requiring similar everyday necessities both now & in future generations too!

Examples of products created using chemical engineering

Chemical engineers are able to create a range of products such as food, fuel, pharmaceuticals, and even cosmetics. Some examples of products created using chemical engineering include:

- Food: Chemical engineering enables food preservation through the use of drying or freezing methods as well as controlling texture and flavour during the production process.

- Fuel: Chemical engineers are essential for creating efficient fuel for automobiles such as ethanol or biodiesel which can be used in place of gasoline.

- Pharmaceuticals: Chemical engineering provides processes for producing drugs more efficiently and with fewer impurities.

- Cosmetics: Formulations used in makeup and skincare products can be created through chemical engineering processes like emulsification.

In addition to these normal everyday items, chemical engineers also use their knowledge to conduct ground-breaking research into advanced materials or develop treatments for diseases such as cancer or diabetes.

Resources

Chemical engineering can be incredibly rewarding and fun for both kids and adults. With the right resources, kids can explore the exciting field of chemical engineering and gain a better understanding of its principles.

In this section, we will be looking at the various resources available to help kids learn about chemical engineering. From online tutorials to books, there are many options to choose from. Let’s dive in and learn more.

Recommended books and websites for learning about chemical engineering

Learning about chemical engineering can be an exciting journey. With the vast resources at your disposal, you can gain insight into the fascinating and sometimes complex world of this science. Here are some recommended books and websites to help you explore and understand the concepts related to chemical engineering.

Books

Some helpful books for learning about chemical engineering include:

- “Introduction to Chemical Engineering Thermodynamics” by J.M. Smith,

- “Chemical Process Control: An Introduction to Theory and Practice” by G Andrew Tucker,

- “Process Dynamics and Control” by Dale E. Seborg, Thomas F. Edgar & Duncan A. Mellichamp,

- “Fluid Mechanics and Heat Transfer” by Lev Patankar & Joseph Ryshkewitch et al.,

- “Chemical Engineering Design Principles: Practice and Economics of Plant Scale Process Design” by T Dow Kunze et al.,

- “Introductory Chemical Engineering Thermodynamics” by J Richard Elliott & Carl T Lira, among others.

Websites

Online resources such as:

- Khan Academy (khanacademy.org),

- MIT’s Open CourseWare (ocw.mit.edu),

- NASA Educational Materials Library (https://siteslibrary-esd112-wa~edupin/sites/er/default/files/NASA_eduRes_Lib_STEM~pdf)

- Chemwiki (chemwiki.ucdavis.edu),

are also available for exploring chemical engineering topics in detail without requiring textbooks or enrolling in regular college courses.

Online courses for learning about chemical engineering

Chemical engineering is an exciting field, and there are many online courses available for those looking to learn more about the subject. From introductory courses about the fundamentals of chemical engineering to specialized courses for advanced professionals in the field, there’s a wealth of learning opportunities available to meet your individual needs.

The following courses may be of interest to someone hoping to learn more about chemical engineering:

- “Fundamentals of Chemical Engineering,” from Purdue University’s Connected Course Library. This course covers topics such as thermodynamic principles, materials equation-of-state models and reaction kinetic models.

- “Introduction to Process Systems for Chemical Engineers,” from MIT OpenCourseWare. This course covers topics such as process system analysis techniques and energy analysis techniques used in chemical engineering calculations.

- A Massive Open Online Course (MOOC) entitled “Chemical Process Principles” from Future Learn. This series provides a survey overview of the various principles underlying chemical processes, including viscosities, activity coefficients and diffusivities among others.

- The Massachusetts Institute of Technology (MIT) offers a course entitled “Reaction Engineering & Catalysis.” This course focuses on understanding Reaction Kinetics and Catalysis – this allows it to be applied broadly across all fields of chemistry with emphasis on developing an overall conceptual framework that can be used from design through manufacturing processes in many different areas.

- The University of Michigan also offers a MOOC called Fundamentals of Chemical Engineering Design which covers topics like systems analysis, process selection and design optimization for chemical engineers; as well as basic tools needed for simulation modeling and process control tools used in today’s Chemical Process Industries.

These are just a few examples but there is much more out there – whether you’re looking for comprehensive lectures offered by well-known universities or tutorials specifically targeted at your desired specialty – research institutes like Coursera® offer access to different learning styles through their libraries so take advantage!

Frequently Asked Questions

Q: What is chemical engineering?

A: Chemical engineering is the branch of engineering that deals with the application of physical science (e.g. chemistry and physics) and life sciences (e.g. biology, microbiology and biochemistry) with mathematics and economics to the process of converting raw materials or chemicals into more useful or valuable forms.

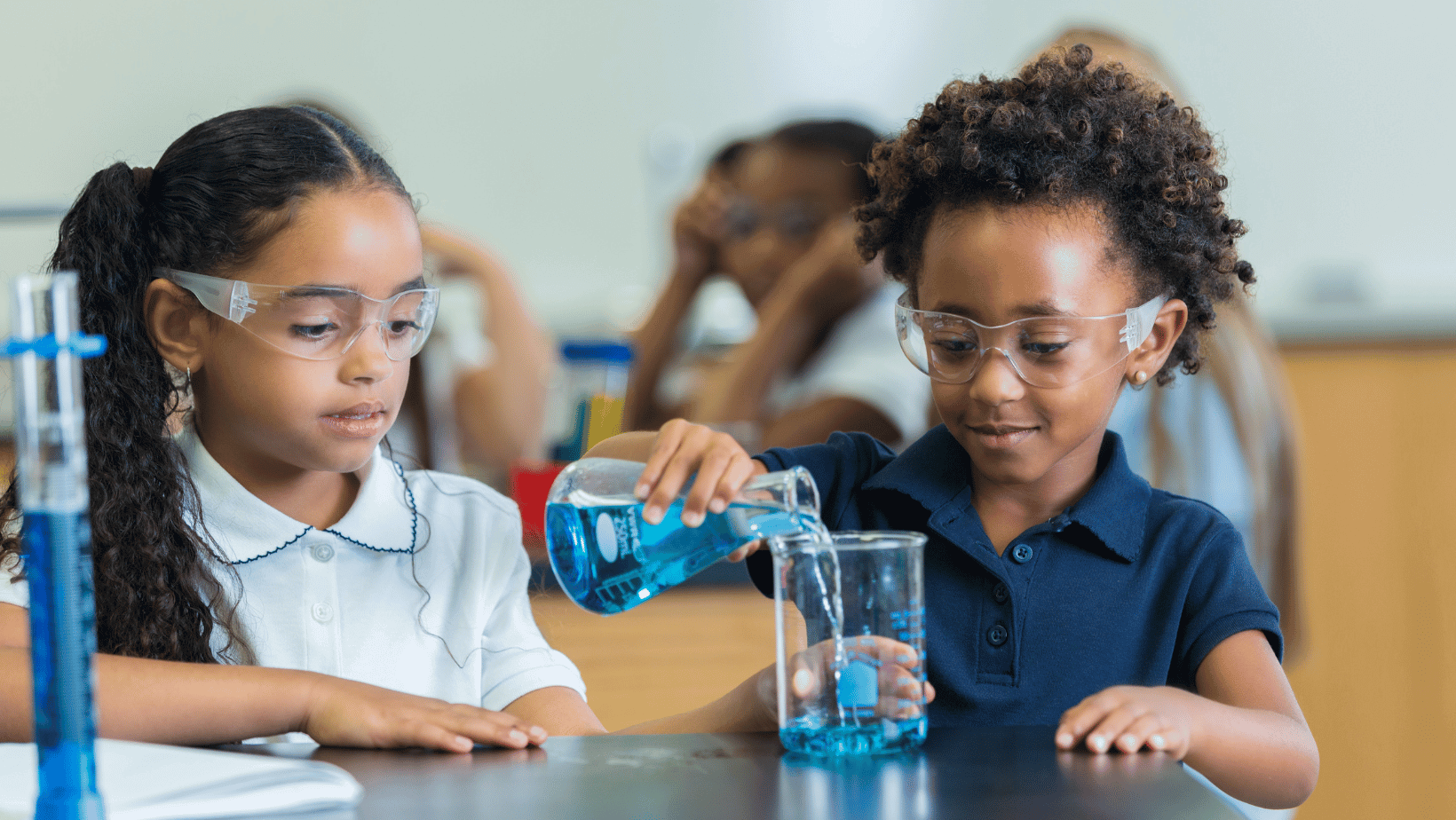

Q: What types of activities can chemical engineering for kids involve?

A: Chemical engineering for kids can involve activities such as learning about the different chemical reactions, exploring various materials and their properties, and experimenting with different types of chemical processes. It can also involve activities such as building and testing new products, designing and constructing models of chemical processes, and learning about the environmental impact of chemical production and usage.

Q: What are the benefits of teaching chemical engineering to kids?

A: Teaching chemical engineering to kids can help them develop critical thinking and problem-solving skills, as well as an understanding of the chemical processes involved in everyday life. It can also help them understand the importance of sustainability and how their decisions can impact the environment. Additionally, it can help them develop a better understanding of the science behind the products and materials they use, and how to use them safely and responsibly.